Your morning brew, made by you, perfected by Breville.

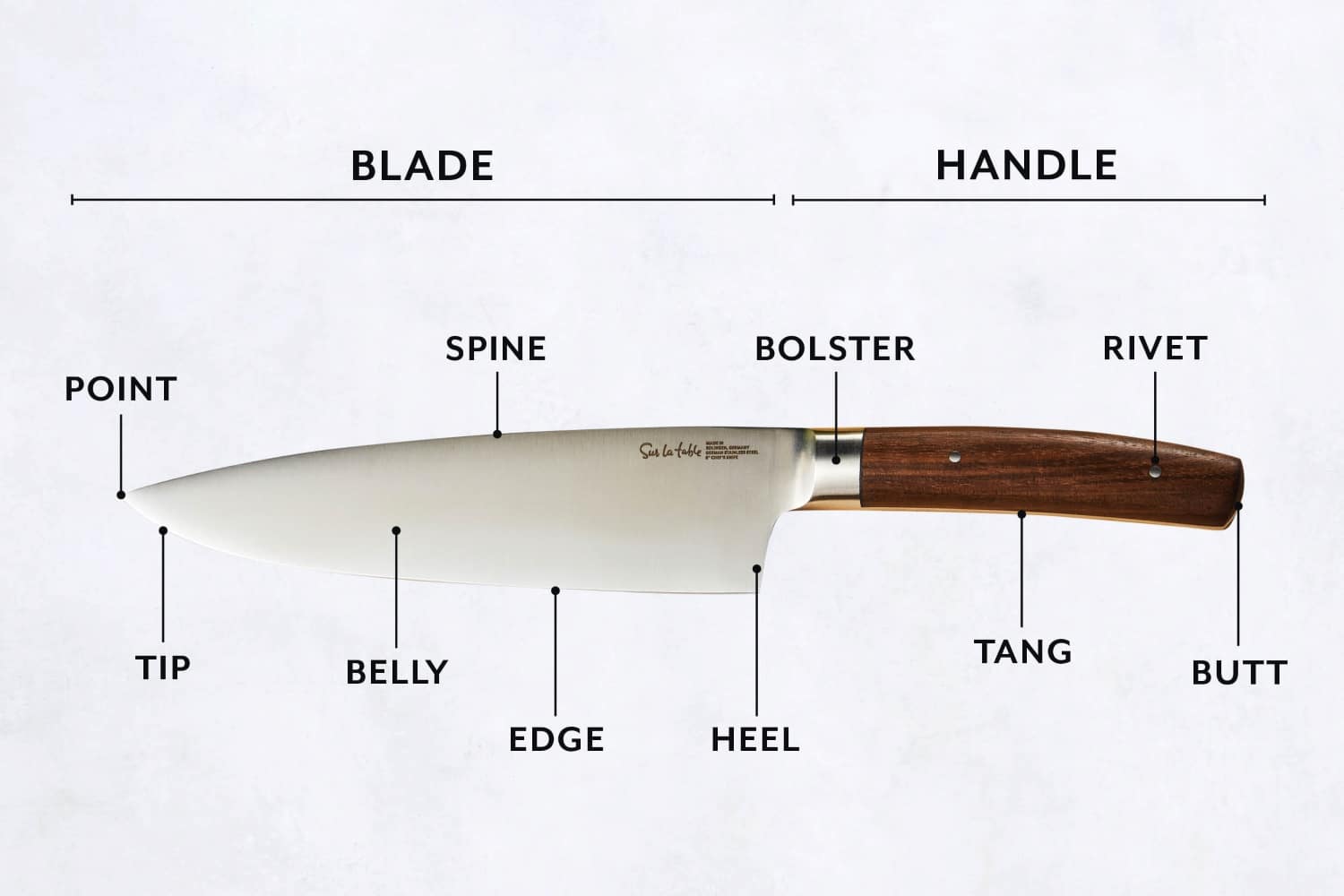

Dicing, chopping, mincing and carving—every cut we make relies on the anatomy of a knife. But there’s more to these tools than just their ability to slice and dice. Each part, from the sharp tip to the end of a handle, plays a pivotal role in how a knife performs across various settings.

From professional chefs to home cooks experimenting with new recipes, understanding the parts of a knife is crucial for selecting the right one for your needs, maintaining it properly, and using it safely. Let’s explore an in-depth look at different parts of a knife and their roles in its functionality.

Hungry for more? Whether you’re gifting them to newlyweds, first time homeowners or looking to upgrade your own set, our line of Sur La Table Classic Knives make a great addition to any kitchen!

The blade is the heart of a culinary knife, central to its function and performance. It is meticulously crafted to handle various tasks in the kitchen, from delicate slicing to robust chopping. Here’s a closer look at the key features and considerations of knife blades:

The choice of blade material significantly affects the knife’s sharpness, durability and maintenance requirements. Common materials include:

The shape of the blade determines its suitability for different tasks. Here are a few common examples:

The construction of a knife blade is a fundamental aspect that determines its quality, balance and longevity. There are primarily two methods used to create knife blades:

The blade of a culinary knife is intricately designed, comprising several key components that are critical to its performance—and contribute to the knife’s cutting ability, balance and overall functionality.

The blade face, or the flat side of the knife blade, plays a pivotal role in how a knife performs during various cutting tasks. It is the broad surface against which food items press as they are being cut, influencing the knife’s stability and the ease of slicing. Here’s a closer look at its importance:

The tip of the knife is the front part, which is typically pointed and sharp. It’s designed for precision tasks like scoring meat, peeling vegetables or delicate slicing. The sharpness of the tip can greatly influence the ease with which you can perform intricate cuts.

Opposite the cutting edge is the spine, the thickest part of the blade. It provides weight and balance to the knife. A heavier spine means more force for chopping through tough ingredients like winter squash or large cuts of meat.

The cutting edge is responsible for the actual cutting and slicing. Understanding the different types of grinds, edge angles and finishes can help select the right knife for specific culinary tasks.

The edge angle of a knife—measured in degrees from the centerline of the blade—significantly affects the knife’s sharpness, cutting performance and durability.

The handle greatly influences the knife’s usability, comfort and control during food preparation. It’s designed to provide a secure grip and minimize fatigue, allowing cooks to perform a variety of tasks with precision and safety.

Handles can vary widely in material, shape and design, reflecting different culinary traditions and ergonomic considerations. Specifically, Western and Eastern handles represent two distinct styles each tailored to their culinary practices:

The butt of a culinary knife, located at the very end of the handle, serves several functional and aesthetic purposes that enhance the overall use and handling of the knife. Here’s a closer look at how different designs of the butt contribute to these aspects:

The bolster of a culinary knife is a crucial feature that serves both functional and safety purposes. It’s the thick junction between the blade and the handle, typically made of the same material as the blade.

For function, the bolster helps to balance the knife. By adding weight between the handle and the blade, it allows for better control of the knife during cutting. This balance is essential for minimizing fatigue during long prep sessions and for achieving precise cuts.

For safety, the bolster acts as a finger guard, preventing the hand from slipping forward onto the blade, which is particularly important when the knife or hands are wet. This can be a significant safety feature in both home kitchens and busy professional settings.

Here’s a quick overview of the different types of bolsters you’ll see in knives:

The tang is an often overlooked yet critical component of any culinary knife. It is the part of the blade that extends into the handle, providing structural strength and balance. The design of the tang can significantly influence the knife’s overall durability and how it feels in the hand during use.

Here’s a deeper look into the types of tangs and their impact on knife functionality:

Hungry for more? Whether you’re gifting them to newlyweds, first time homeowners or looking to upgrade your own set, our line of Sur La Table Classic Knives make a great addition to any kitchen!

Join The Conversation